Introducing our Laboratory dedicated to Large-Scale Purification

Ten years ago, Reach Separations was established primarily to provide discovery-scale chiral chromatography, up to a few grams of racemate. It soon became evident that our clients would also require separations on a larger scale in order to support projects further from discovery into development.

What also became clear is that in order to run an efficient process, dedicated instrumentation would be required and it wasn’t possible to run these projects alongside discovery-scale separations.

Back in 2020 (which feels like a lifetime ago!), we took the plunge and took on a new large lab at Biocity Nottingham with the intention of establishing a Large-Scale purification facility. Two years on and the lab is in full operation, handling projects from 50g to 1 kilogram across a diverse array of fields including Chiral Separations and non-UV active Lipid purification.

Why have a separate lab?

Firstly, the growth in demand for development scale chiral separations; The past few years have been characterised by a consistent increase in enquiries for chiral separations of >100g racemate. Secondly, we’ve also seen increased interest in impurity isolations, requiring us to process large quantities of crude material to obtain enriched fractions. Whilst our existing facilities were able to cope, creation of a new facility has allowed us to streamline processes and reduce processing time, without having an impact on discovery scale operations.

The Facility

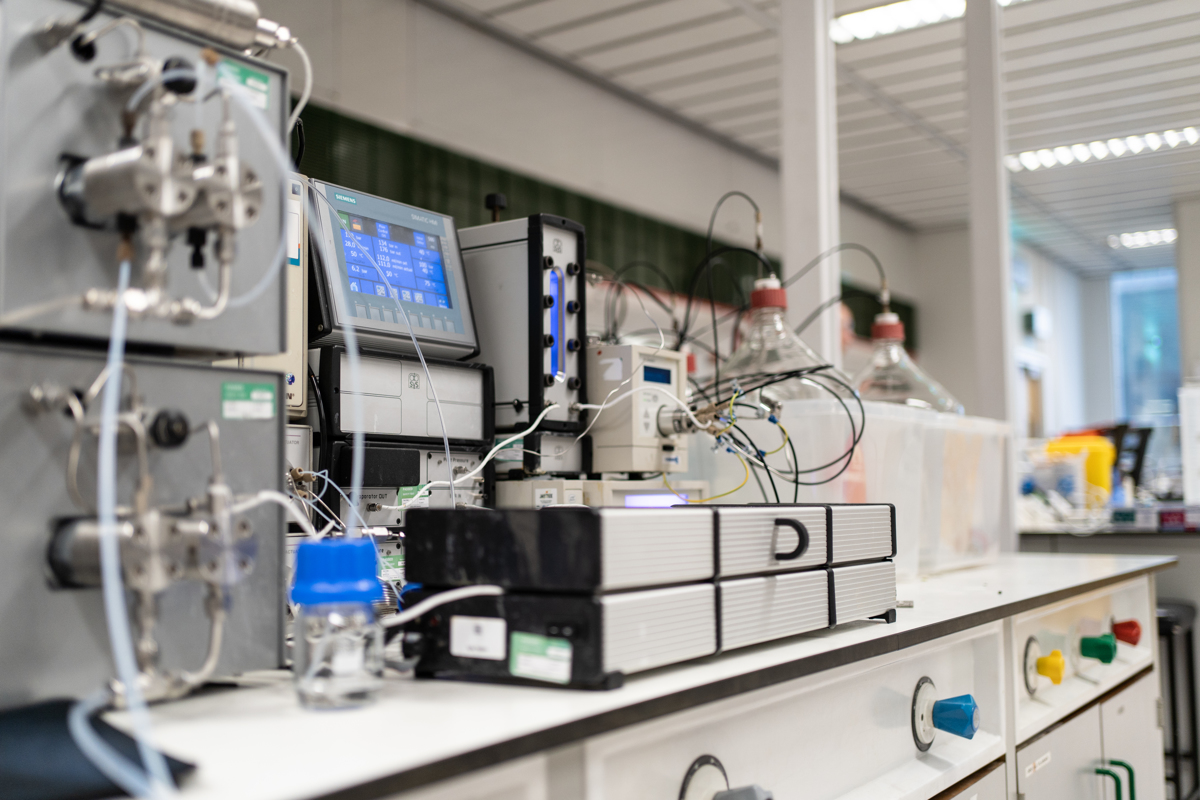

The premises comprises of 1,580 square feet of laboratory and office space at Biocity. The lab space features two large ABsys SFC systems and two Gilson HPLC systems which will focus on processing large amounts of material for chiral separations and impurity isolations.

Gas delivery and storage can be an issue with heavy usage of SFC, with cylinders quickly clogging up a laboratory. To solve this issue, our new facility has a dedicated gas delivery room. This houses all the CO2 required for SFC operations and is delivered to the instruments via a booster pump. This simple upgrade in infrastructure vastly reduces the time spent swapping out gas cylinders and creates a safer working environment for the team.

To compliment the high flowrates required to separate large amounts of material, we’ve invested in new technologies to keep up with solvent evaporation. The new kit includes; Two new large freeze-driers, two large 20L rotary evaporators and a suite self-filling continuous rotary evaporators. Highly efficient solvent removal allows us to run instruments for longer, opening up an opportunity for 24/7 processing.

Our latest upgrade to the Large-Scale laboratory has been investment in non-UV detection techniques to further diversify the chemical space in which we’re able to operate. Over the past year we have brought in an analytical HPLC-CAD system, along with a preparative ELS detector. This new kit has enabled us to take on challenging new Lipid purification projects and successfully isolate hundreds of grams of pure material despite a lack of chromophore.

To find out more about our services, click here.